Be talonized.

A North American First – designed with the environment first in mind!

“TalonGrip” cedar bead & cove strips are available in 3/16″ & 1/4″ thickness in 6′ to 7′ 10″ lengths (shipped in Canada) and 6′ to 8′ 3″ lengths ( shipped in US) to build any design available from Jarvis Boards, Laughing Loon Kayaks, Guillemot Kayaks, Green Valley Boat Works/John Winter’s designs, Bear Mountain Boats, Redfish Kayaks and Sandy Point Boat Works.

Our range of sizes of “TalonGrip” strips allows you to build any project you have in mind.

It has never been easier to build your wonder craft with shorter length, high quality components. No zig zags on the face of the strips but a fine vertical line as it should be. The added beauty is that the “Talons” are orientated in the proper direction giving maximum strength and flexibility once glued up. At TotemStrips we continually strive to innovate and improve our product line so that you will be able to stand back and admire your efforts with pride in knowing you chose the right supplier.

” The real McCoy”

Simply “Prestufit” as you strip. It really is that simple. After choosing your strips press two together ( the length required for your craft) on a flat surface and glue a second one in place directly above in the cove to act as a stiffener holding every thing together. Push the strips together gently to seat every thing in place Don’t forget to apply a small amount of glue to the Talons with an acid brush or dip one end in glue. Keep a damp cloth on hand to wipe off excess glue and allow to cure for about an hour before applying to the hull. Apply the built up pieces at the sheer line on the forms to start your first row. Simply apply strips sliding and locking them into place as if you were laying bricks remembering to colour match and stagger your joins. You can even trim off any overhanging piece and use it to start your next row which will reduce your wastage considerably. You cannot get any greener than that. The result is a very elegant clean tight join without nails or staples. These components do not have to be clamped as the talons are the clamps when pushed together which really speeds up construction. We think that’s awesome, a world first in green Cedar strip construction.

“Nice things come in small packages”, as the saying goes. Imagine, high quality components, building any length boat you want out of an 8′-6″ package. There are savings to be had with “TalonGrip” strips. Consistent colour, Vertical grain, without run out.

“TalonGrip” Courier b&c strips – 6′ to 7′ 10″ – shipped by UPS in Canada

“TalonGrip” Courier b&c strips – 6′ to 8′ 3″ – shipped by UPS in US

The lion’s share are 7′6″, and 8′ in length.

Prices are subject to change without notice.

| 3/16″ x 5/8″ | 3/16″ x 3/4″ | ||

| W.Red Cedar b&c | .70/lft | .70/lft | |

| Yellow Cedar b&c | .70/lft | .70/lft |

|

|

1/4″x 5/8″ | 1/4″ x 3/4″ | |

| W.Red Cedar b&c | .70/lft | .70/lft | |

| Yellow Cedar b&c | .70/lft | .70/lft |

For our US customers, just think, no more bond or brokerage fees.

No more extra length charges on ground freight shipments.

Economically shipped direct to your door world wide via UPS.

Worry free shipping fully insured.

High quality materials only used in our exclusive in house manufacturing process.

Justin McAllister’s Bob’s Special canoe – stunning!

Justin McAllister’s Bob’s Special canoe – stunning!

Justin McCallister- An Architecture graduate at the School of Architecture in Chicago embraced our philosophy as part of his thesis, building a real beauty with “TalonGrip”.

In the photos below Justin McCallister’s ” Bob’s Special” canoe as it was in progress using “TalonGrip” Courier Strips

“A couple things I really liked about the talon grips and using the shorter pieces in general was the ease of handling and installing shorter pieces vs a 16’ long piece especially when you have a cove full of glue. The talon grips worked nicely on the install because I could push the joint together when installing the strip whereas a normal splice would slip.

It was also nice when fairing the canoe with the talon grips since the joint was pretty well level across the two strips.

Staggering the splices was relatively easy as well since every cutoff could be flipped around and used to start the next row with the sawn off part extending beyond a bow or stern a couple inches to be cut off again.

Overall I am really satisfied with how the strips worked out, they were easy to install and made the hull build much quicker. “

OTHER CUSTOMERS who have used our “TalonGrip” strips to build their projects!

At Totemstrips our “number one” concern since day one, has always been a balance between preservation of the environment as well as building your dream craft.

Western Red Cedar truly is the “Mahogany of the West” which other lower cost alternative species cannot match. When we mill our wood for “TalonGrip” strips it is hard not to chuckle inside, thinking that we are cheating mother nature with her permission getting so much more. Truly , “less is more”.

The Birch bark canoe being the first plywood boat in existence five thousand years ago, was a purely pragmatic response to environmental conditions which helped shape it. No two were the same. With all too many discussion boards these days it is too easy to overthink the process as cognitive overload kicks into high gear as “we want to do it right” , when really , there are many ways to get to the same destination. That is what makes boatbuilding so special and exciting ; when you have to improvise and trust your instincts as you are in the thick of it having a blast.

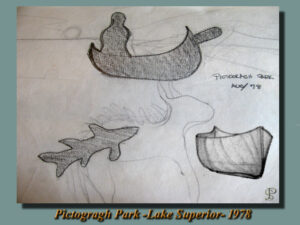

Sketches by the author with an imagined unfinished dream canoe to this date.

These sketches from the past as well as stumbling across a piece of decaying birch bark on my walks in the Ontario bush, have helped in shaping our philosophy.

We visualise an indigenous builder of the past who walks into the bush with something as simple as a piece of sharpened flint . He cuts some White Cedar, splits it into many pieces of several sizes. One vertical layer of ribs pressed against another layer of White Cedar planking at 90 degrees to the ribs with another layer of birch bark rotated at 90 degrees again and a plywood hull has been created. A dab of super adhesive, Pine tar is then applied to seal the stitched together seams.Then he pulls Spruce roots to lash Spruce strips together for gunnels. Well, not quite as simple as that, but you get the picture. Seemingly in no time at all, he paddles out of the bush with his creation. When this craft has outlived it’s usefulness and it is left on the bank somewhere it simply expires slowly unravelling itself and becoming part of the earth again in a non toxic manner.

You just can’t get any Greener than that ; so we beg the question.

Who really, is further up the evolutionary ladder?

A whopping 96% of our old growth forests on Vancouver Island are gone forever!! No matter where we are in BC we witness the savage destruction of our forests and are reminded of it daily as barge after countless barge of logs are towed past on the way to the sorting grounds. Very little of this wood is available to British Columbian’s and Canadians. It is mostly pre sold being shipped out of the country and it seems that there is very little left for us to value add and create meaningful lasting employment.

It is not a pretty picture as all reforesting has until just recently been only reforested with mono-cultures of one species for maximised profit when re-harvesting and very little cedar has been replanted. This leaves the mountains fallow and brittle with the third generation being worthless to harvest, ready to ignite into flames earlier every spring due to the effects of “Global Warming”

With Heli -logging now the norm, few mountain tops have been left unscathed. With so much of the environment pillaged, most wildlife looses ground as it is displaced into ever smaller remaining pockets of forests still left.

So for this reason we are compelled to act and encourage people to work with all lengths of cedar when building their water craft.

This has been our motivating factor for creating “TalonGrip” strips.

No Butts about it! Simply superior in every way.

Colour matching is a breeze since we have provided colour matched bundles. Staples are no longer necessary where the strips are butted together on the moulds. These joins do not need to line up on station moulds. For those of you used to scarfing strips together: honestly why bother when we have done the work for you! No wastage whatsoever since you can simply cut off any extending piece and simply use it to start your next row! The joins are tight leaving a barely visible line. You just can’t get any greener than this.

The lion’s share are 7′6″, and 8′ in length.

All ends are carefully wrapped before packaging in Cardboard or in “Totem Box”

Accurate and precise machining assures a high quality product.